In the world of industrial machinery, maintaining optimal performance is paramount for productivity and safety. Vibrations, however, present a persistent challenge, stemming from various sources such as unbalanced loads, rotating components, and external forces. To combat this issue, anti-vibration rubber mounts emerge as a crucial solution, offering a buffer between machinery and its environment.

Understanding Vibrations

Vibrations in machinery are dynamic forces that result in oscillations, impacting performance and structural integrity. These vibrations can lead to accelerated wear and tear, decreased accuracy, and compromised safety if left unchecked. Understanding the causes and effects of vibrations is essential for implementing effective mitigation strategies.

Role of Anti-Vibration Rubber Mounts

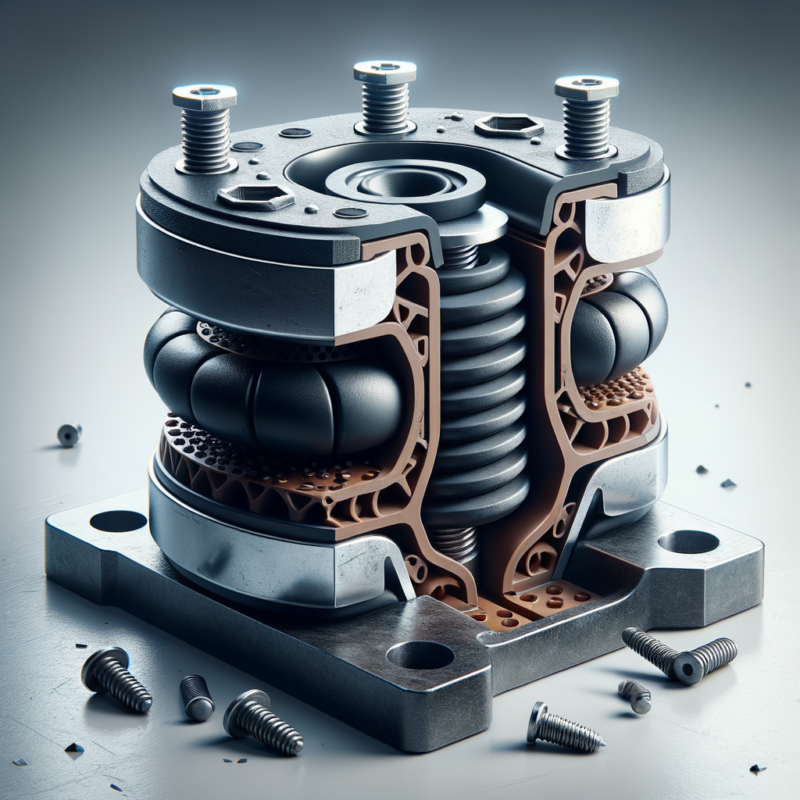

Anti vibration rubber mounts serve as isolators, attenuating vibrations and preventing them from propagating throughout the machinery. By utilizing the elasticity and damping properties of rubber, these mounts absorb energy and dissipate it as heat, effectively reducing the amplitude of vibrations and minimizing their impact on performance.

Types of Anti-Vibration Rubber Mounts

Anti-vibration rubber mounts come in various forms to suit different applications and environments. They can be classified based on material composition, with options including natural rubber, neoprene, and silicone. Additionally, there are different designs available, such as cylindrical mounts, sandwich mounts, and bushings, each offering unique benefits and performance characteristics.

Applications of Anti-Vibration Rubber Mounts

The versatility of anti-vibration rubber mounts makes them indispensable across a wide range of industries and applications. In industrial settings, they are commonly used to isolate heavy machinery, such as engines, pumps, and compressors, from the surrounding structure to minimize vibration transmission. In the automotive industry, these mounts play a critical role in enhancing ride comfort and reducing noise levels. Furthermore, in aerospace applications, they are employed to isolate sensitive instruments and components from the vibrations induced by aircraft engines and flight conditions.

Factors to Consider When Choosing Anti-Vibration Rubber Mounts

When selecting anti-vibration rubber mounts for a particular application, several factors must be taken into account to ensure optimal performance and longevity. These factors include the load capacity of the mounts, environmental conditions such as temperature and exposure to chemicals or fluids, and installation requirements such as mounting orientation and hardware compatibility. By carefully evaluating these factors, users can choose mounts that meet the specific demands of their application and provide reliable vibration isolation.

Installation and Maintenance Tips

Proper installation and maintenance are essential for maximizing the effectiveness and lifespan of anti-vibration rubber mounts. During installation, attention should be paid to ensuring correct alignment and torque values to prevent premature failure or misalignment. Additionally, regular maintenance, such as visual inspections and cleaning of mounts, can help identify potential issues early and prevent costly downtime or damage to machinery.

Cost-Benefit Analysis

While the initial investment in high-quality anti-vibration rubber mounts may seem significant, the long-term benefits far outweigh the costs. By reducing the transmission of vibrations and minimizing wear and tear on machinery components, these mounts can help extend the lifespan of equipment and reduce maintenance costs. Furthermore, the improved performance and reliability provided by anti-vibration mounts can lead to increased productivity and profitability for businesses in the long run.

Case Studies

Real-world examples and case studies illustrate the tangible benefits of incorporating anti-vibration rubber mounts into machinery systems. From industrial applications to automotive and aerospace use cases, these studies demonstrate the significant improvements in performance, reliability, and overall operational efficiency achieved through the implementation of effective vibration isolation solutions.

Conclusion

In conclusion, anti-vibration rubber mounts play a crucial role in improving machinery performance by mitigating the adverse effects of vibrations. Their ability to isolate machinery from external disturbances helps minimize wear and tear, reduce maintenance requirements, and extend the lifespan of equipment. By investing in high-quality mounts and adhering to proper installation and maintenance practices, businesses can enhance productivity, ensure safety, and maintain a competitive edge in today’s dynamic industrial landscape.